Extended production for SAP Business One

Apply for a free SAP Business One trial now

Efficient production processes for your company

Extended production for SAP Business One

In today’s highly competitive industry, efficient and transparent production processes are the key to a company’s success. With an extended production solution for SAP Business One, small and medium-sized companies receive a powerful platform that is specially tailored to the requirements of the manufacturing industry. You optimize your production processes, improve resource planning and increase transparency along the entire value chain.

This solution enables you to digitally transform your production, reduce costs and shorten delivery times – all in a user-friendly and scalable environment. This solution is aimed at:

- Small and medium-sized manufacturing companies with complex production processes

- Industries such as mechanical engineering, metal processing, electronics manufacturing, plastics industry and more

- Companies that use SAP Business One and want to digitally optimize their production

Flexible, customizable processes.

Flexible processes for individual requirements

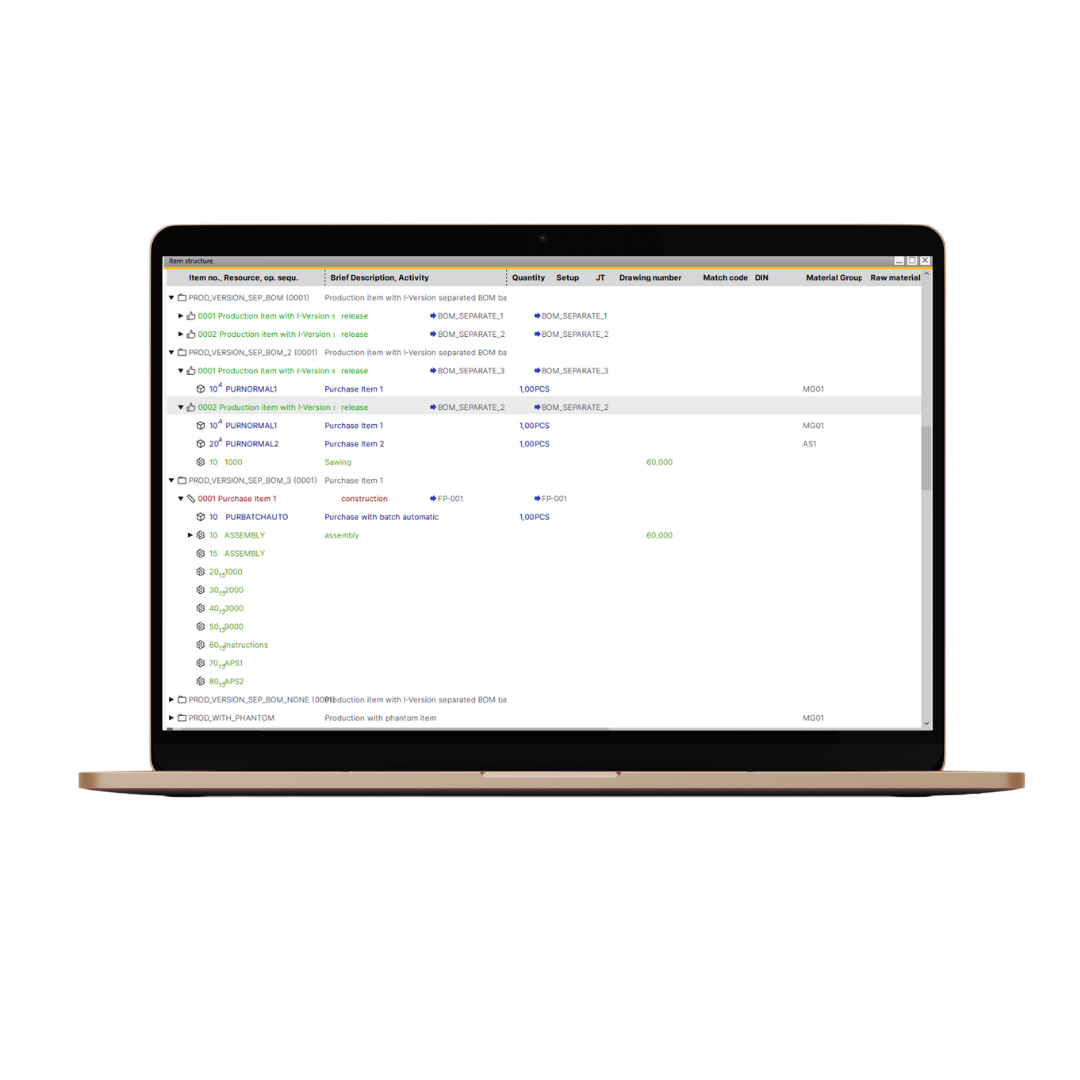

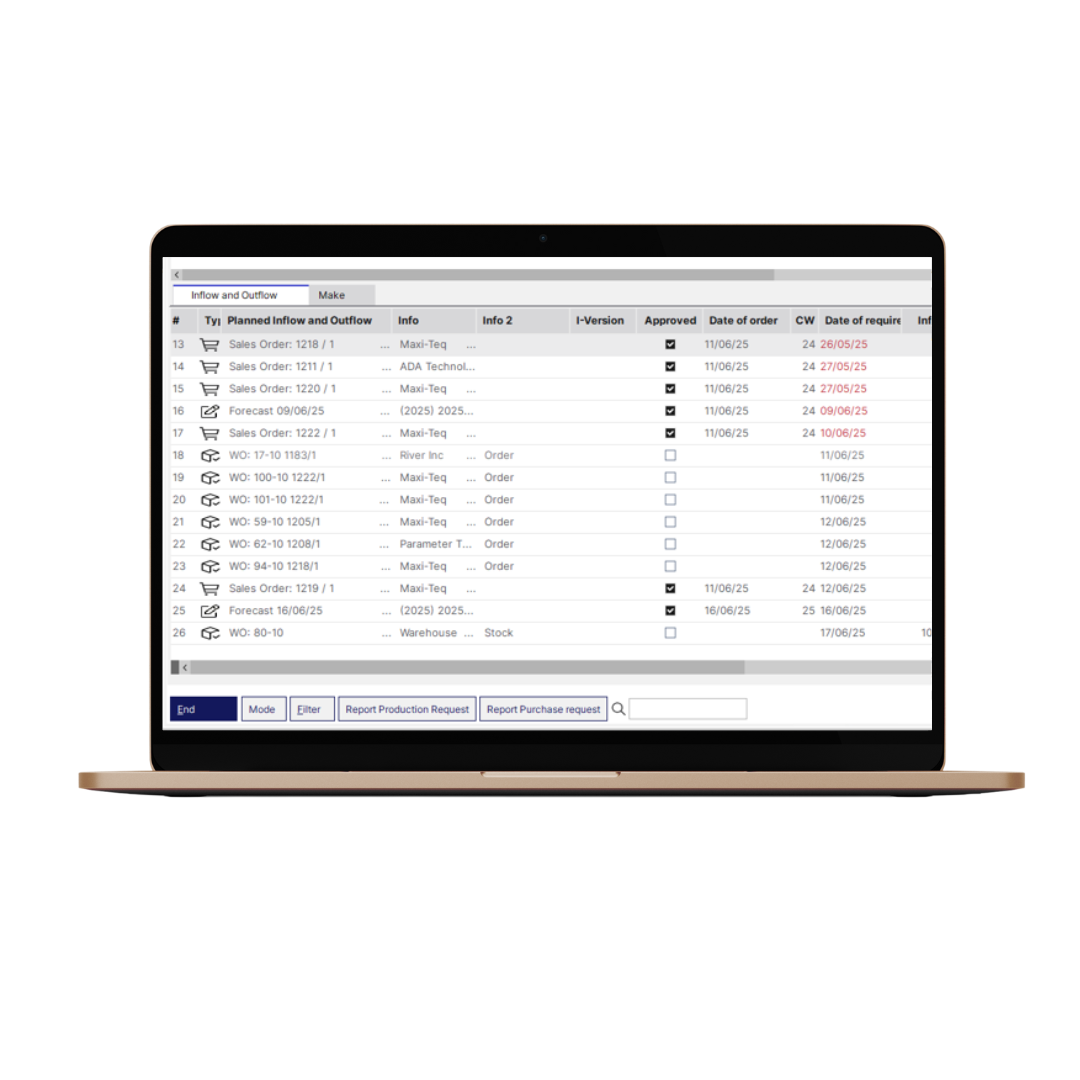

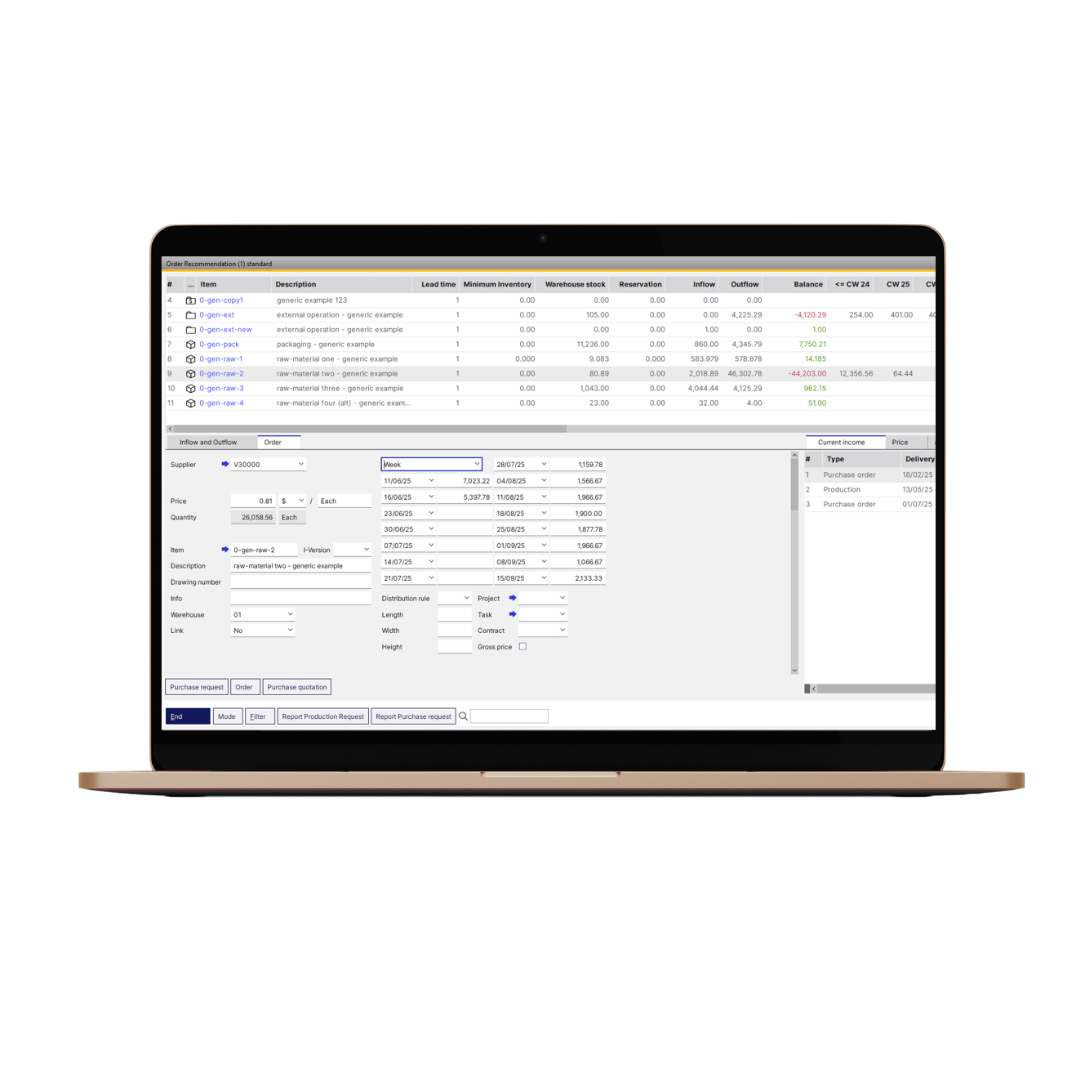

The extended production solution is a modular system that significantly extends the vertical integration of SAP Business One. It maps the entire production process – from planning, materials management and production control through to quality control and production data acquisition.

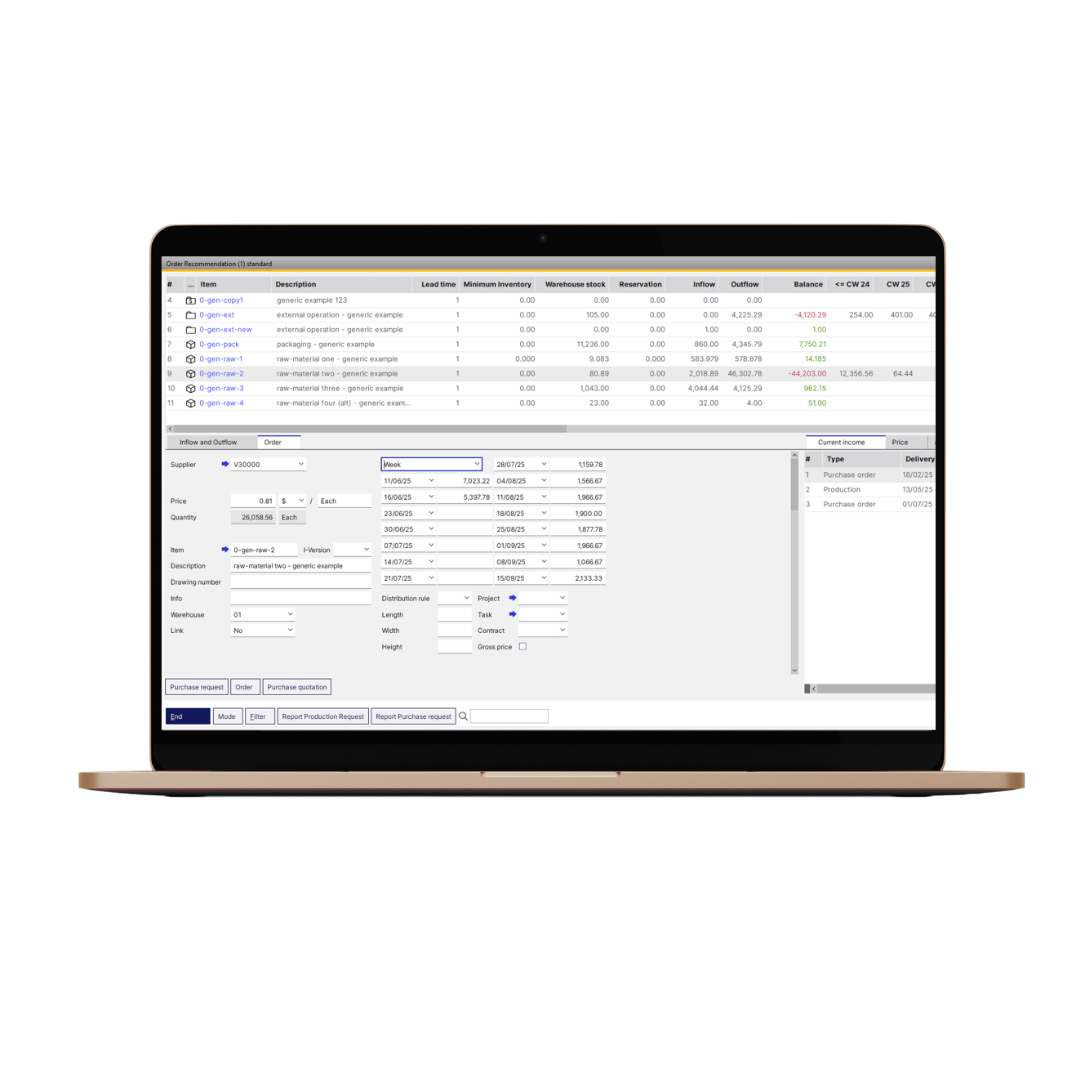

MRP / MRP II - Intelligent demand planning for every production line

Production order management - flexible, transparent, controllable

Integration Hub - networked processes, central database

Quality control & release - quality that is created in the process

Materials management - transparent stocks, automatic flows

Version / revision management - everything under control

Calculation & product costs - clarity for every order

External production - external partners, seamlessly integrated

How to sustainably optimize your production with intelligent integration, scalability and transparency

Advantages of the extended production solution for SAP Business One

- Seamless integration:: Full integration with SAP Business One avoids duplicate data entry and increases process automation.

- Scalability: Ideal for small and medium-sized companies with growing production requirements.

- User-friendliness: Intuitive operation ensures rapid acceptance by all users.

- Transparency: All production data is stored centrally and available at all times for well-founded decisions.

- Cost optimization: Reduce storage costs and downtimes through intelligent planning.

- Flexibility: Modular design enables individual adaptations to your production processes.

Frequently asked questions

The solution digitizes your production processes through full integration with SAP Business One. This means that all important data - from order creation and material availability to production execution - is recorded in real time and mapped transparently. Paper-based processes and isolated solutions are a thing of the past. This gives you an end-to-end digital process chain that reduces errors, increases productivity and ensures complete traceability of your production.

In contrast to conventional PPS systems, which often work in isolation, the extended production solution is fully embedded in the SAP Business One ERP system. This eliminates the need for duplicate data maintenance and you benefit from automated ordering processes, real-time stock levels and end-to-end transparency across all areas of the company. In addition, the solution has been specially developed for SMEs and can be flexibly adapted to your individual production requirements without being complex and cumbersome.

The modular structure of the solution allows production processes to be mapped entirely according to your requirements - be it discrete production, variant production or contract manufacturing. Work plans, parts lists and production resources can be configured individually. Existing machine controls or external systems can also be integrated via interfaces. This means that the solution remains flexible and scalable even in the event of future process changes or growth.

Integrated material requirements planning (MRP) analyzes all production orders and existing stock levels in order to trigger orders for raw materials and components in good time. This allows you to avoid both excess stock and bottlenecks. Using just-in-time principles, the solution optimizes your warehousing and helps to reduce capital commitment and storage costs. At the same time, you increase your delivery reliability and can react more quickly to market requirements.

Quality management is integrated into the production processes right from the start. You can define inspection points at which the manufactured products or assemblies are checked - whether during the manufacturing process or during the final inspection. The inspection results are automatically documented and can be traced at any time. In the event of deviations, measures can be initiated automatically to eliminate sources of error and ensure product quality.

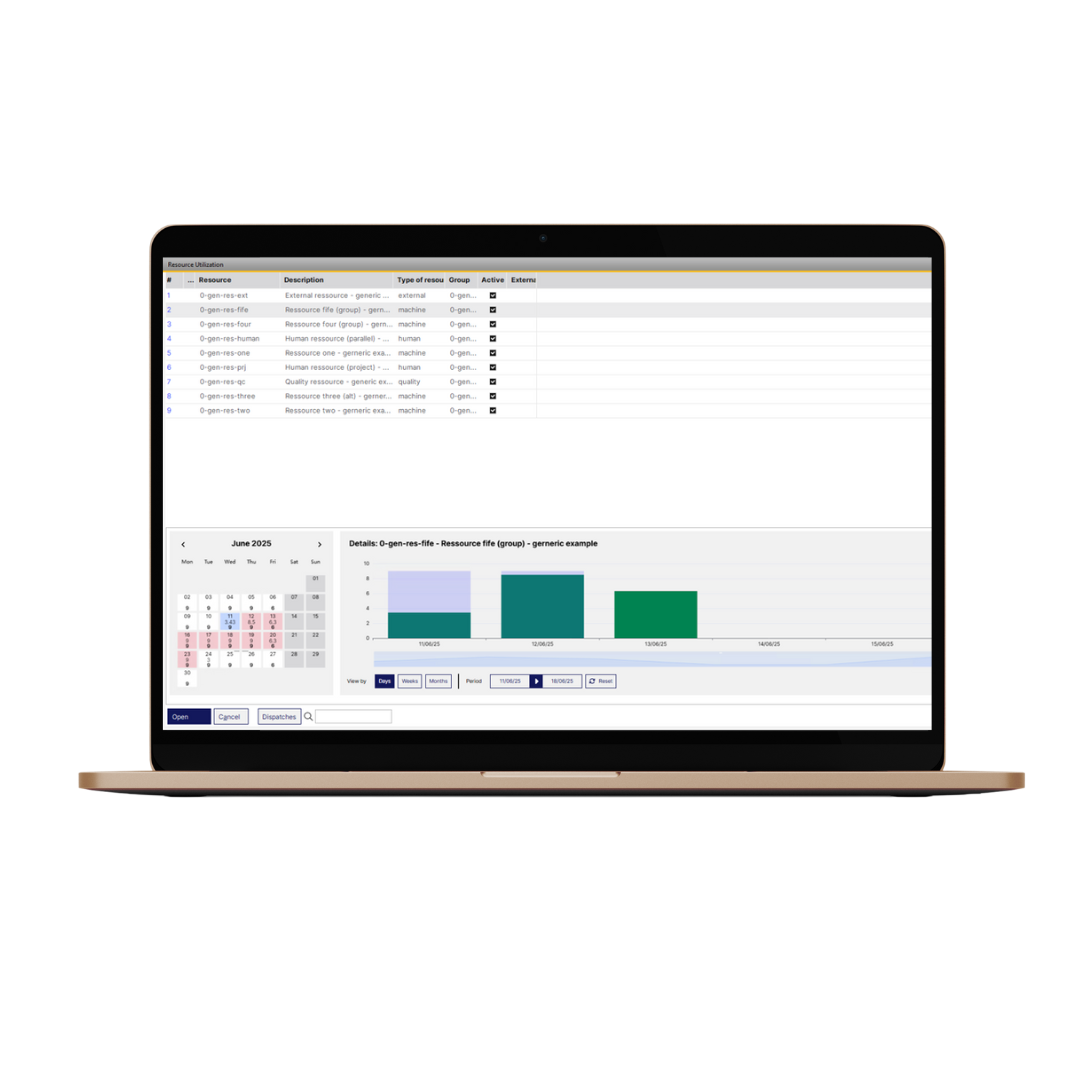

Production data acquisition enables you to record production times, machine running times, material consumption and employee deployment in real time directly at the production site. This data is evaluated centrally, which helps you to identify efficiency losses, minimize downtimes and optimize your production planning. Mobile devices or terminals on machines facilitate input, and automated reports give you valuable insights into your production.

The implementation takes place step by step, starting with a detailed analysis of your existing processes. Together, we define priorities and adapt the solution to your needs. Agile project methods are used to make the implementation transparent and flexible, so that your employees are involved at an early stage and training can take place in a targeted manner. Data migration is carried out carefully to ensure a smooth transition. After the go-live, a competent team supports you to ensure a successful start.

More Add Ons

Your enhancements for SAP Business One

Optimize processes, automate workflows and get more out of your system.

Automatic invoice management

Digitize your incoming invoices and automate approval, pre-assignment and transfer to SAP Business One - GoBD-compliant and without media discontinuity.

ELO sidebar

Connect ELO directly to SAP Business One - for legally compliant archiving, smart workflows and centralized access to all documents, without system changes or media disruptions.

Webshop connection

Automate data exchange between your online store and SAP Business One. Product, customer and order data are automatically synchronized - for smooth processes.